Are you looking for PCR consumables that can match the automatic pipetting workstation?

Are you worried that the PCR plate frame material is too soft and cannot withstand the gripping pressure of the robot arm?

Are you worried that the PCR plate will deform after thermal cycling?

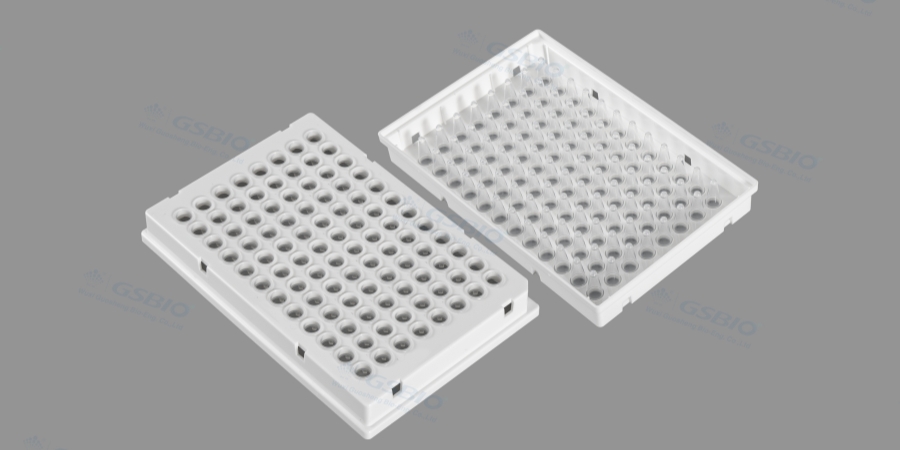

What is a Dual-material PCR Plate?

The dual-material PCR plate utilizes two-color injection molding technology. The reaction plate frame is made of polycarbonate material, and the reaction wells are made of the same polypropylene material as the conventional PCR plate, effectively combining the advantages of both materials. Specifically, the plate frame is made of polycarbonate (hard shell) material, which has excellent mechanical stability and flatness; the reaction wells, made from polypropylene, exhibit good thermal conductivity, and the highly uniform thin walls facilitate efficient heat transfer during the thermal cycling process.

What are the differences from conventional PCR Plates?

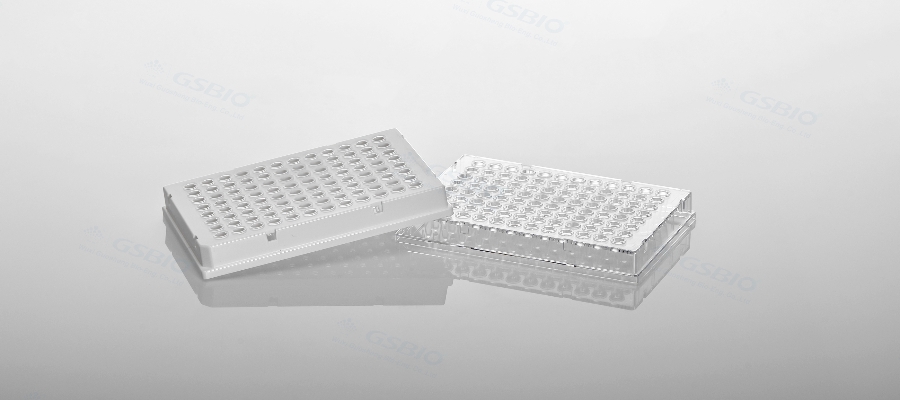

1. Stable when exposed to heat: It does not deform when heated, and remains flat after PCR thermal cycles; therefore, dual-material PCR plates can be used in any downstream steps of automated and high-throughput workflows;

2. Anti-warping and durable: It has anti-warping and excellent stability during automated robotic arm processing, high-speed centrifugation and storage (up to -80°C), and is durable;

3. Seamless fit: The hard frame PCR plate has a higher hardness than ordinary PCR plates, and is the best choice for heat sealing. It will not "warp" and is convenient for each hole to "get evenly wet" when applying the film, achieving good sealing.

Post time: Mar-14-2025